Redesign of the IS-1 in order to work out problems but

also to reduce the weight, improve the armor, provide an improved shape, and

simplify production.

Well-armed and well-armored, its chief shortcoming was

the slow rate of fire of the main gun, the consequence of separate projectiles

and cartridges.

Early in the autumn of 1943, the Soviets

were completing the first of three prototypes of their new IS-1 (IS-85) heavy

tank using design experience gained from their previous KV heavy tank projects.

These new IS (Iosef Stalin) prototypes were systematically demonstrated before

the special commission from the Main Defense Commissariat and with the

completion of general factory trials the IS design was approved for production.

Although the first production vehicles mounted the 85mm gun also seen on the

T-34/85 medium tank, these initial IS-1 tanks were shortly converted to carry

the 122mm M1943 D-25 gun before they were provided to the tank troops. The new

IS-2 tank weighed little more than its predecessor KV tank, but it had thicker

and better-shaped armor that provided vastly improved protection. The overall

weight was kept low by using a more compact hull and component design, as we

shall see later. Once the 122mm gun was installed and series production

continued, the new "Tiger Killer" was officially named the IS-2 Heavy

Tank, although its weight and armor characteristics closely coincided with the

German Panther medium tank. By the end of 1943, the Kirov Factory had produced

a total of 102 IS-2 heavy tanks and they were used for the first time in

February of 1944 at Korsun Shevkenskovsky. Although there were a number of

external improvements to the IS-2 during its production and field use, there

were relatively few internal changes made over the years.

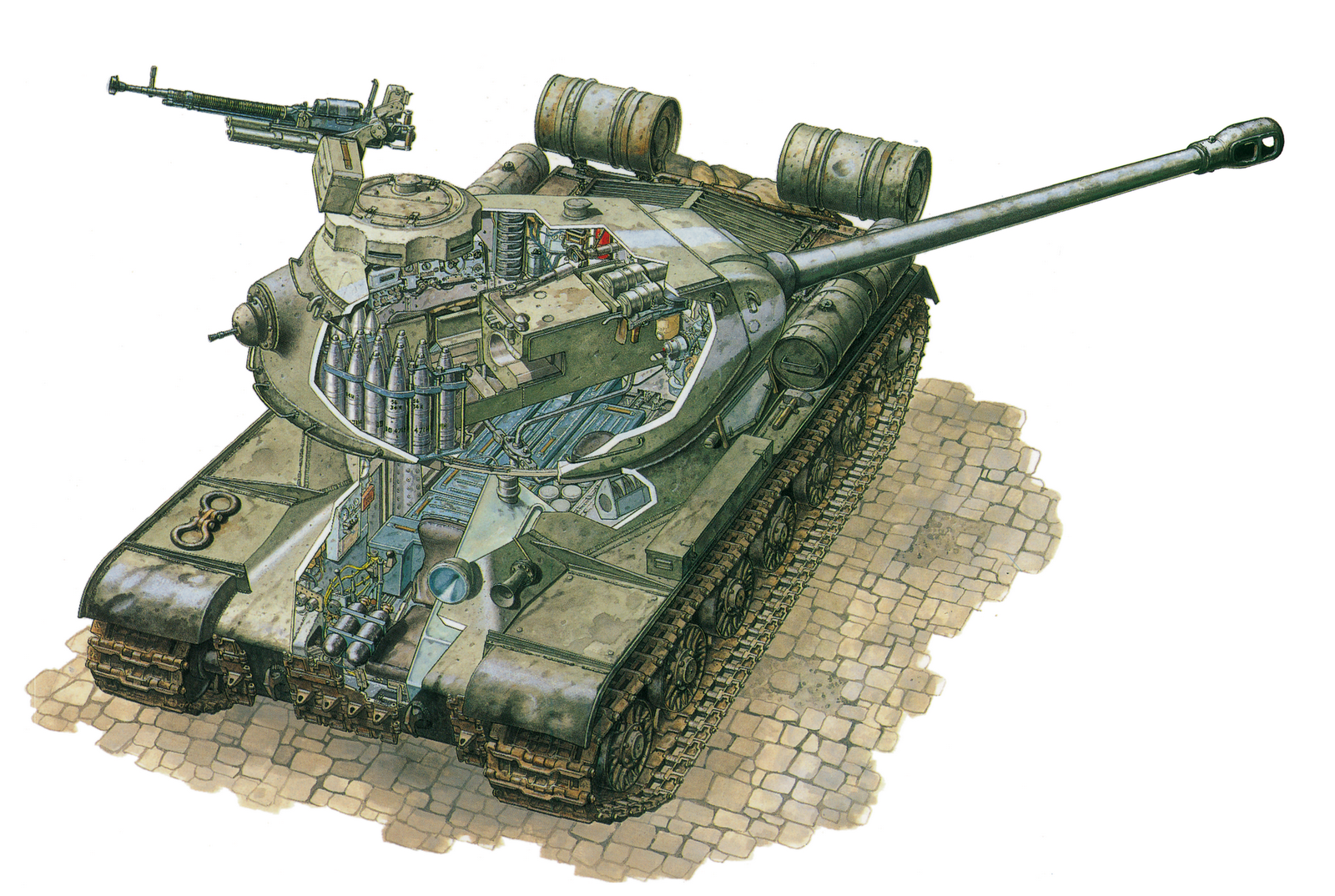

The IS-2 hull was designed after ample

combat experience with the KV tanks, and you can see that the hull actually

overhangs the tracks. It is an interesting hull design in that the bow casting

is welded directly to a circular casting for the base of the turret. Additional

rolled armor plates are then added to form the rest of the hull sides, ending

at a sloping rear plate that covers the engine and transmission. Both heavy

armor castings and rolled plate are utilized in the hull, and the castings in

the bow provide around 122mm (4.7in) of frontal armor. This initial bow design

was based on the earlier KV-13 tank layout.

Although the first IS-2 vehicles used this

curved and gently sloping front bow casting, it was later replaced in 1944 with

either a new casting or a welded plate nose, both of which had a straight

60-degree slope from glacis to the top of the hull. The Uralsky Factory of

Heavy Machinery (UZTM) plant made the welded noses, while factory #200 made the

cast types. The IS-2 was one of the first production Soviet tanks to remove the

traditional second driver/hull machine gunner from the bow of the tank,

providing additional space for fuel tanks. In place of a ball mounted MG on the

front plate, a DT machine gun was mounted on the right side of the hull behind

the driver and up near the turret ring. It was fired via a remote control

firing cable from the driver's position.

The new tank design illustrates the

Soviet's mid-war combat strategy reorientation from using tanks for infantry

assault to tank hunting and killing machines. As a result, the second driver in

the hull was deemed unnecessary and the crew was reduced from the traditional

five soldiers to only four, the driver then placed in a central position in the

bow. The commander is located inside the turret at the left rear, the gunner is

to the left of the main gun, and the loader is to the right. Both the gunner

and loader are provided with over-head periscopes and the commander has a

non-rotating turret cupola incorporating vision blocks that provided a

360-degree field of view. He also has a rotating periscope in his cupola hatch.

A round roof hatch that is flush with the turret roof is provided for the

loader on his side of the turret.

Initially, the 122mm L/43 gun mounted in

the cast turret retained its original interrupted screw breech, showing its

ancestry from the already proven D-19 field gun. But the screw field gun breech

was replaced (by early 1944) with a horizontally sliding block, semi-automatic

type, and of course the recoil cylinders and elevating mechanisms were altered

from the field gun to fit into a turret. Because the 122mm ammunition rounds

were so huge, they were provided in separate pieces, a projectile and a charge

cartridge, but even so only 48 complete rounds could be stored inside the tank.

Although a number of ready rounds were strapped into easily reached racks in

the turret, most of the ammo was stored in sheet metal boxes down on the hull

floor and, as we have seen in the T-34/76, these boxes were often covered with rubber

floor mats. There was no turret basket in the IS-2; the turret crew seats were

either suspended from the turret and rotated along with it (commander's) or the

seats were supported on tubes that rose from the center of the floor and also

rotated with the turret (gunner and loader).

By the time the IS tanks were being

manufactured, the Soviets had plenty of technical experience with casting large

pieces of armor, and the IS-2 turret became one of the biggest castings they

manufactured during the war. Although Western writers have tended to criticize

the coarse standard of Soviet armor finish, the urgency of tank manufacture in

1943 did not warrant lavishing extra time and energy on unnecessary

refinements. Over the course of its production, the turret was gradually

changed. The early IS-2 tanks that were manufactured in 1943 were originally

designed to have installed a D-5T 85mm gun in their turrets, and they had a

narrow opening for the telescopic sight just to the left of the gun. When the

122mm D-25T gun was placed inside these same turrets, it was very hard for the

gunner to use his telescopic sight, as it was so close to the gun. So, in

mid-1944 a new turret with a larger sight opening that was also shifted

slightly to the left was produced. Also at this time the thickness of the

turret's mantlet was increased, along with the lower hull sides. The new turret

also moved the commander's cupola slightly to the left and the gunner's PT4-17

periscopic sight in the turret roof was changed over to a Mk.4 type. About this

time a Model 1938 12.7mm DShK anti-aircraft machine gun was installed outside

on the commander's cupola to provide some protection from strafing German

aircraft.

Production dates: April 1944–June 1945

Number produced: 2,250

Manufacturer: Factory No. 100,

Kirovskiy Works (Chelyabinsk)

Crew: 4

Armament: 122mm gun D-25T; 1 x 12.7mm DShK

machine gun; 2 x 7.62mm DT machine guns

Weight: 101,184 lbs.

Length: 32’

Width: 10’2”

Height: 8’10”

Armor: maximum 129mm; minimum 60mm

Ammunition storage and type: 28 x 122mm;

945 x 12.7mm; 2,330 x 7.62mm

Power plant: V-2-IS (V2-K) V-12 600-hp

diesel engine

Maximum speed: 23 mph

Range: 100 miles

Fording depth: 4’3”

Vertical obstacle: 3’2”

Trench crossing: 8’2”

No comments:

Post a Comment